Faces and Stories of Our Community

We love our members at ACS and want to share their stories far and wide. Keep checking back for more of their stories! If you’re an ACS member who’d like to be featured, contact us.

Lively Run Dairy

One of the longest operating dairies in the country, Lively Run Dairy began production in 1982 in the Finger Lakes region. After moving to the U.S. from Germany, Steve and Susanne Messmer took over operations in 1995, and the family business was launched. Now, Steve and Susanne, sons, Pete and Dave Messmer, and business partner, Katie Shaw own Lively Run Dairy, cementing its place in the cheese industry. “Our mission is to make delicious artisan cheese inspired by the Finger Lakes and its culture,” says Katie.

One of the longest operating dairies in the country, Lively Run Dairy began production in 1982 in the Finger Lakes region. After moving to the U.S. from Germany, Steve and Susanne Messmer took over operations in 1995, and the family business was launched. Now, Steve and Susanne, sons, Pete and Dave Messmer, and business partner, Katie Shaw own Lively Run Dairy, cementing its place in the cheese industry. “Our mission is to make delicious artisan cheese inspired by the Finger Lakes and its culture,” says Katie.

The team at Lively Run makes unique cheeses using cow and goat milk from local New York state family farms. It is important to them to not only use quality milk to make their award-winning cheeses, but to also support local farmers. They are a part of a strong community that wants their producers to thrive, especially these days. Hoping to inspire customers to “live healthier, happier lives,” the Lively Run team traditionally hosts tours and events (including goat yoga!) to help teach them where their food comes from, and the benefits of supporting local agriculture.

These days Lively Run is facing the same challenge as many cheesemakers and shops – how to get their products to customers during a pandemic. “We quickly pivoted because we had to, sales dropped by 50% because of restaurants and food service outlets closing,” explains Katie. They were able to launch an online store and successfully promote it to customers, all in a matter of days. Inspired by the overwhelming support, the team hosted a virtual cheese hour with cheese boxes available for pre-order, and they’re participating in more virtual tastings with local breweries and vineyards.

These days Lively Run is facing the same challenge as many cheesemakers and shops – how to get their products to customers during a pandemic. “We quickly pivoted because we had to, sales dropped by 50% because of restaurants and food service outlets closing,” explains Katie. They were able to launch an online store and successfully promote it to customers, all in a matter of days. Inspired by the overwhelming support, the team hosted a virtual cheese hour with cheese boxes available for pre-order, and they’re participating in more virtual tastings with local breweries and vineyards.

Lively Run has recently been in the news for their philanthropic efforts, raising money to produce cheese for local food banks. Katie recalls, “We were upset watching our dairy farmer friends dumping milk, knowing how much hard work they put into their animals and product.” Their program meets two needs: creating an outlet for the excess milk and helping get food to those who have lost their jobs because of this pandemic. And while donations and have come from all over the world, it is their local area that has shown overwhelming support. “It’s a tightknit community that really believes in low food waste and helping each other out,” says Katie.

Lively Run has recently been in the news for their philanthropic efforts, raising money to produce cheese for local food banks. Katie recalls, “We were upset watching our dairy farmer friends dumping milk, knowing how much hard work they put into their animals and product.” Their program meets two needs: creating an outlet for the excess milk and helping get food to those who have lost their jobs because of this pandemic. And while donations and have come from all over the world, it is their local area that has shown overwhelming support. “It’s a tightknit community that really believes in low food waste and helping each other out,” says Katie.

Now they’ve set up a nonprofit, Lively Run Cheese for New York with the Center for Transformative Action, expanding their efforts beyond their community. With their cheesemaking process becoming more labor intensive now because of a shift to online sales, and the attention they’re getting from their nonprofit initiative, their team is busier than ever. They were able to avoid layoffs or furloughs and are hiring more part time staff to help with packaging. “We’re a small, collaborative team and that’s a big reason we’ve been so successful.”

Learn more about Lively Run Dairy at livelyrun.com or by following them on Facebook.

Specialty Food Sherpa

Patrick Bleck has spent over 20 years in the specialty food business, from distribution to sales. Five years ago, he pursued a long-held goal; he started his own manufacturers’ representative company, Specialty Food Sherpa. A true Sherpa, he guides his clients through marketing, navigating retail and distribution, publicity, and everything in between. “My goal is to help them get to the next level, refining and refreshing their brand and vision every step of the way,” says Patrick.

An ACS member since 2016 and in business since 1994, Specialty Food Sherpa, works with four artisan cheesemakers in the Pacific Northwest: Twin Sisters Creamery, Ferndale Farmstead, Appel Farms, and Face Rock Creamery. Each one brings their own unique products and stories to the artisan cheese community:

Appel Farms – Ferndale, WA

Appel Farms – Ferndale, WA

Producing Farmstead artisan cheese for over 30 years, the Appel family produce a diverse line of cheese including their award-winning Maasdammer semi-hard swiss. Founder Jack Appel immigrated from Holland to the U.S., establishing the now third-generational family dairy farm and cheesemaking business. These days, their Cheese Shop Drive Thru has reopened for business and their cheeses can be found at local Washington retailers.

Face Rock Creamery – Bandon, OR

Face Rock Creamery – Bandon, OR

Sitting on the Oregon coastline, Face Rock leans into the stormy, salty climate to produce their terroir-driven cheeses made with milk from local grass-fed cows. They honor traditional practices to make their cheddars, producing award-winning cheeses including an ACS gold medalist, Clothbound Cheddar in 2019. The creamery remains open for visitors, cheese can be purchased online, and a selection of prepared foods are available for takeout.

Ferndale Farmstead – Ferndale, WA

Ferndale Farmstead – Ferndale, WA

A three-generational maker of Italian heritage cheese, Ferndale uses a three-tier, “seed to cheese” closed-loop approach. They make their 2019 ACS gold medalist, fresh Ciliegine Mozzarella, and aged cheeses from their own milk, produced by their cows that are fed with the crops they nurture and grow. Ferndale Farmstead products can be purchased at retailers across the Northwest.

Twin Sisters Creamery – Ferndale, WA

Twin Sisters Creamery – Ferndale, WA

In 2013, owners Lindsay and Jeff Slevin joined the cheesemaking world, producing the first batch of their award-winning Whatcom Blue. They focus on quality by using raw milk from a local dairy farm to make their aged blue and farmhouse cheeses. Today, they offer online shopping, delivery, and curbside pickup for their own cheese as well as products from other makers and partners.

Just like with most cheesemakers, COVID-19 greatly impacted these four companies’ traditional distribution channels. Even the way consumers shopped and purchased food, especially cheese, changed overnight. Patrick recalls, “Consumers were bypassing the deli, bypassing the specialty cheese to get to the items with longer shelf-lives and toilet paper.” One of his clients, Lindsay Slevin, co-owner at Twin Sisters Creamery, reached out to a retailer contact, expressing the urgency of the situation American cheesemakers were in. That contact, Cheryl-Ann Jones, Food Service Sales Manager at Haggen Food, jumped into action. Within a week, Cheryl-Ann launched a month-long BOGO promotion in Haggen stores featuring Patrick’s four clients and eight additional Northwest cheesemakers previously not featured in the Haggen cheese case. “The response was phenomenal, and sales were incredible. Not only were they selling specialty cheese to help producers now, but they created new, loyal customers that had never stopped at the deli section before,” says Patrick.

Just like with most cheesemakers, COVID-19 greatly impacted these four companies’ traditional distribution channels. Even the way consumers shopped and purchased food, especially cheese, changed overnight. Patrick recalls, “Consumers were bypassing the deli, bypassing the specialty cheese to get to the items with longer shelf-lives and toilet paper.” One of his clients, Lindsay Slevin, co-owner at Twin Sisters Creamery, reached out to a retailer contact, expressing the urgency of the situation American cheesemakers were in. That contact, Cheryl-Ann Jones, Food Service Sales Manager at Haggen Food, jumped into action. Within a week, Cheryl-Ann launched a month-long BOGO promotion in Haggen stores featuring Patrick’s four clients and eight additional Northwest cheesemakers previously not featured in the Haggen cheese case. “The response was phenomenal, and sales were incredible. Not only were they selling specialty cheese to help producers now, but they created new, loyal customers that had never stopped at the deli section before,” says Patrick.

Other local retailers in the area were inspired to run similar promotions. Some, like Haggen, are even covering the cost of the promotion, not charging the producers anything. “I’ve never seen [a retailer] step up to support an entire industry like that,” says Patrick of Haggen and other retailers in his area. To date, many national and local retailers have also launched programs to support local creameries.

Now, the challenge is to continue to promote and adapt to the new way people are buying things. “Communication is key,” Patrick emphasizes. “It’s inspiring to see retailers supporting artisan cheesemakers right now. We have to figure out a way to keep this going through the rest of this crisis and beyond.”

Learn more about these ACS members:

- Specialty Food Sherpa: specialtyfoodsherpa.com

- Appel Farms: thecheesefarm.net Facebook, Instagram

- Face Rock Creamery: facerockcreamery.com Facebook, Instagram, Twitter

- Ferndale Farmstead: ferndalefarmstead.com Facebook, Instagram

- Twin Sisters Creamery: twinsisterscreamery.com Facebook, Instagram

Heber Valley Artisan Cheese

For nearly 100 years, the Kohler family, owners of Heber Valley Artisan Cheese & Kohler Creamery, has been producing premium milk at their family dairy nestled in the quaint community of Midway, Utah. Dairy farming and cheesemaking is in their blood. Grant & Caralee Kohler are the third-generation family to operate the dairy, along their five children who make up the fourth generation. After struggling with inconsistent dairy commodity prices, the Kohler family opted to fulfill a lifelong dream: (1) build their own creamery and (2) make their own award-winning artisan cheese.

For nearly 100 years, the Kohler family, owners of Heber Valley Artisan Cheese & Kohler Creamery, has been producing premium milk at their family dairy nestled in the quaint community of Midway, Utah. Dairy farming and cheesemaking is in their blood. Grant & Caralee Kohler are the third-generation family to operate the dairy, along their five children who make up the fourth generation. After struggling with inconsistent dairy commodity prices, the Kohler family opted to fulfill a lifelong dream: (1) build their own creamery and (2) make their own award-winning artisan cheese.

In 2011, they launched Kohler Creamery, home to Heber Valley Artisan Cheese, creating a unique dairy farm-to-creamery experience and keeping traditions alive while producing award-winning fresh and aged cheeses. It is important to the Kohler family that the lifeblood of their company, their cows, get the best care possible, utilizing robotic milkers and care equipment on the animals’ own terms. “A farmer is in it because they love it. We’re rewarded every day because of our lifestyle and the animals we work with, that’s our payday.” said Russ Kohler, farmer and cheesemaker.

The Kohler Family, ACS members since 2012, has leaned in on their mission to help others experience the difference of the farmer’s touch. Located in the mountains of Utah, just a few miles outside where the 2002 Olympic ski events took place, Heber Valley’s community is an affluent one, highly trafficked by tourists. They aim to showcase the farm experience and their animals to an urban crowd through their hands-on events, tours, and workshops. “Our goal is to show people how much farmers care about the quality of their products. We want that to shine through from the baby calf we’re raising to the cheese you’re eating,” says Russ.

Keeping that mission front of mind while adjusting operations for social distancing and stay-at-home orders has been an unexpected but not impossible challenge for the Kohler family. “When COVID-19 hit, three of our four channels disappeared overnight: tourism, our storefront, and food service,” says Russ. In response, they found ways to keep orders flowing, staff employed, and the animals fed, launching curbside service, and increasing promotion of online ordering.

But one hurdle remains for Heber Valley Cheese and most cheesemakers – how to get the food supply to consumers now that distribution channels are impacted. “The food shortages happening aren’t always because the product isn’t available, but because of distribution channel challenges.” Russ cites an overnight shift in the way the public buys cheese as is part of this challenge stating, “It’s important for consumers to understand that there is plenty of food, we just have to get innovative and work as a community to get our products to them.”

With an abundance of product, Heber Valley Cheese has given several thousand pounds of cheese to local food banks to help get food to those in their region that need it most. “COVID-19 is a major health issue but it’s also causing a lot of financial issues for families,” says Russ. His team is doing all they can to combat this, working with local programs like Curbs + Kindness who raise money to help supplement the cost of making the cheese so more can be made for food pantries. “[Dairy farmers and cheesemakers] are a vital part of the food chain and we’ve done our best, as all farmers across the country have, to keep people fed.”

The Kohler family is also looking forward, thinking of new ideas to expand their successful agritourism programming once things open back up. “People will be excited to get out and do things after being cooped up for so long, we want to give them hands-on experiences to open their eyes to the American farming way of life.”

Learn more about Heber Valley Cheese Company at hebervalleyartisancheese.com or by following them on Facebook or Instagram.

Nettle Meadow Farm & Sanctuary

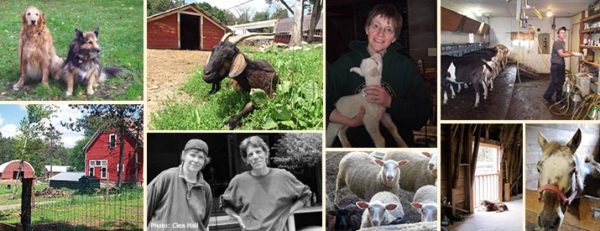

Nettle Meadow Farm, an ACS member since 2010, is experiencing what many in our industry are experiencing – a large drop in the demand for cheese and a need to find new ways to get their products into homes. Founded in 1990, Nettle Meadow is a farm animal sanctuary, dairy, and cheesemaking organization, creating aged, semi-aged, and fresh flavored cheeses. From their start, owners Lorraine Lambiase and Sheila Flanagan have prided themselves on not just their multi-award-winning cheeses, but also their commitment to the hundreds of goats, sheep, and other retired and rescued farm animals in their sanctuary. “We are all about our animals, the clean and beautiful cheeses we make, and taking pride in both,” says Renata Pilato, Sales Manager for Nettle Meadow.

Nettle Meadow Farm, an ACS member since 2010, is experiencing what many in our industry are experiencing – a large drop in the demand for cheese and a need to find new ways to get their products into homes. Founded in 1990, Nettle Meadow is a farm animal sanctuary, dairy, and cheesemaking organization, creating aged, semi-aged, and fresh flavored cheeses. From their start, owners Lorraine Lambiase and Sheila Flanagan have prided themselves on not just their multi-award-winning cheeses, but also their commitment to the hundreds of goats, sheep, and other retired and rescued farm animals in their sanctuary. “We are all about our animals, the clean and beautiful cheeses we make, and taking pride in both,” says Renata Pilato, Sales Manager for Nettle Meadow.

And while their focus remains on their animals and making great cheese, this pandemic has forced the Nettle Meadow team to explore new distribution channels. With their usual outlets such as restaurants, schools, and caterers shut down, they quickly launched a brand-new e-commerce site, selling many of their award-winning cheeses online. “People still need to eat, and we want to make it easy for them to find our cheese,” says Renata. They’re also offering discounts and working directly with retailers to appeal to consumers and keep their cheese front of mind.

Living by their mantra of “Every Choice Matters,” Lorraine and Sheila have always been involved in their community. The area where Nettle Meadow is located has mixed options for food availability, but with many of those options closing, there is a gap to be filled. To help fill that gap and keep product from going to waste, Nettle Meadow has donated over 5,000 lbs. of cheese to local food banks. They are now working with a state-wide group to keep those efforts going, providing cheese to food pantries across Eastern New York state.

For the team at Nettle Meadow, it is also important to think past the COVID-19 situation and how they will remain relevant and prepared for what’s to come. Renata explains, “Eventually this will all be behind us, and we need to prepare for that day in addition to reacting to what’s happening now.” While their usual distributors are not all actively buying and others’ orders have dropped significantly, Nettle Meadow is still sending cheeses and materials out, and offering virtual tasting sessions. “We’re trying to lay groundwork so we can jump back in once our partners come up for air.”

For the team at Nettle Meadow, it is also important to think past the COVID-19 situation and how they will remain relevant and prepared for what’s to come. Renata explains, “Eventually this will all be behind us, and we need to prepare for that day in addition to reacting to what’s happening now.” While their usual distributors are not all actively buying and others’ orders have dropped significantly, Nettle Meadow is still sending cheeses and materials out, and offering virtual tasting sessions. “We’re trying to lay groundwork so we can jump back in once our partners come up for air.”

Even during this economic crisis, Nettle Meadow is continuing with their plans to build a new creamery that will double their operations. To them, this expansion is critical to their future security and growth. “We’ve applied for as much financial stimulus as possible, but it’s not enough,” says Renata. “It’s up to us to do the rest and make sure our business, our employees, and our animals are taken care of.”

Learn more about Nettle Meadow Farm at nettlemeadow.com or by following them on Facebook or Instagram.

Sweet Freedom Cheese

Jessica Keahey, ACS CCP™ and owner of Sweet Freedom Cheese in Bentonville, Arkansas, is adapting on the fly during this pandemic, shifting her business from being a cut-to-order cheese shop and café with a successful wholesale operation, to a much-needed neighborhood grocery with curbside pickup. “Our top priorities are to stay open, bring great cheese to people, keep our staff employed, all while focusing on the safety of the public and our mongers,” Jessica says. With much of the local food market not available to the community because of COVID-19 mandates, Sweet Freedom Cheese is filling that need by getting creative and putting as much cheese as possible into homes.

Jessica Keahey, ACS CCP™ and owner of Sweet Freedom Cheese in Bentonville, Arkansas, is adapting on the fly during this pandemic, shifting her business from being a cut-to-order cheese shop and café with a successful wholesale operation, to a much-needed neighborhood grocery with curbside pickup. “Our top priorities are to stay open, bring great cheese to people, keep our staff employed, all while focusing on the safety of the public and our mongers,” Jessica says. With much of the local food market not available to the community because of COVID-19 mandates, Sweet Freedom Cheese is filling that need by getting creative and putting as much cheese as possible into homes.

Jessica and her team are focused on safety and customer experience, taking orders and cheesemongering over the phone, offering curbside pickup, and starting local delivery for those that can’t make it to the store. They’re also focused on supporting cheesemakers that are struggling now. In addition to the artisan cheese, sandwiches, and cheese boards available for stand-alone ordering, Sweet Freedom Cheese is creating curated boxes of products and prepared foods, ready for customers to create delicious meals and snacks at home. “Producers are relying on us to get their cheese out there, especially softer cheeses which are in trouble, and we want to support them.”

Jessica and her team are focused on safety and customer experience, taking orders and cheesemongering over the phone, offering curbside pickup, and starting local delivery for those that can’t make it to the store. They’re also focused on supporting cheesemakers that are struggling now. In addition to the artisan cheese, sandwiches, and cheese boards available for stand-alone ordering, Sweet Freedom Cheese is creating curated boxes of products and prepared foods, ready for customers to create delicious meals and snacks at home. “Producers are relying on us to get their cheese out there, especially softer cheeses which are in trouble, and we want to support them.”

And the ideas keep flowing! Sweet Freedom Cheese now sells staples boxes full of American and International cheeses as well as local butter, bread, alcohol, and other specialty items. They’re contributing cheese and milk to a local chef who is creating customized kits full of regional products, working with their key distributor on a bulk order program to help move unused food service cheese, and are launching a plethora of other ideas including an online cheese subscription program. “Things are changing daily in our community so it’s difficult to gauge all needs, but we’re flexible,” Jessica explained. “We’ll try something and if it doesn’t work, come up with a different idea, whatever it takes.”

Jessica’s not only flexing to meet the food needs of her area, she’s also leaning in on Sweet Freedom Cheese’s year-round mission to be a “Force for Gouda”. “We have the benefit of being open and because of that, we feel that we have the responsibility to help our community.” With many local restaurants closing during this crisis, distributors and makers have fewer outlets through which to sell their products, leaving much of it going to waste. To help combat this, Sweet Freedom Cheese is partnering with local food banks, private sponsors, and still-open restaurants to get unused food into the hands that need it, including hospital healthcare workers. Jessica is also continuing to support nonprofits like Rockin’ Baker Academy by including their bread in the staples boxes so they can stay open, and provide stability for the underserved young adults that rely on them. Even Sweet Freedom’s customers are joining the Force for Gouda, donating in support of their social mission. “This sort of charitable giving from our customers to help us continue these kinds of efforts is really inspiring.”

Learn more about Sweet Freedom Cheese at sweetfreedomcheese.com or by following them on Facebook, Instagram, or Twitter.

Urban Stead Cheese Co.

Andrea Siefring-Robbins and Scott Robbins, co-owners of and husband and wife team at Urban Stead Cheese Co. in Cincinnati, Ohio, are putting community first as they pivot their business model during the COVID-19 pandemic. ACS members since 2017, Urban Stead recognized the need to get creative in order to keep their doors open and their cheese flowing.

Andrea Siefring-Robbins and Scott Robbins, co-owners of and husband and wife team at Urban Stead Cheese Co. in Cincinnati, Ohio, are putting community first as they pivot their business model during the COVID-19 pandemic. ACS members since 2017, Urban Stead recognized the need to get creative in order to keep their doors open and their cheese flowing.

“Our typical model is us operating as a cheesemaker with a tasting room, where we serve and sell cheese alongside other local food offerings and a full bar, in addition to our wholesale business,” described Andrea.

But with shelter-in-place and social distancing orders in affect, the team at Urban Stead Cheese Co. had to think of new ways to get their products in the hands of consumers. So, they converted their customer experience into an online one-stop grocery for all their patrons’ needs. While still selling their cheeses, cheese curds, and a variety of quark-based spreads, they’re also selling other household staples they don’t typically carry. These staples include meats and eggs from a local farmer, a local honey, a neighborhood coffee roaster’s beans, bread from their bread maker, Swabian-style sourdough pretzels from their pretzel maker (they serve his pretzels with their beer cheese), milk from a local dairy, vegetables, fruits and butter from their local distributor, desserts from their baker, and Urban Stead’s selection of local beer and fine wines.

By offering an online shopping program, they are keeping their business open, creating a safe and contact-free shopping experience, and offering a retail outlet for other makers in their community to sell their products. “It’s funny to say that it’s felt good continuing to write checks to these local makers, but it’s felt incredibly important to keep money moving and to play our small part in keeping the desperately-needed funds flowing to these partners,” says Andrea.

Continuously operating under their motto of “Cheddar for the Better,” they’re also contributing to those in need in their community in other ways. They donate cheese curds to local food rescue programs including a restaurant that is creating meals for local healthcare workers.

Learn more about Urban Stead Cheese Co. at urbansteadcheese.com , or follow them on Instagram and Facebook.

Old Brooklyn Cheese Company

Michael Januska, founder of Old Brooklyn Cheese Company in Cleveland Ohio, made the jump to the cheese industry in the same way as many of his peers, in pursuit of a new passion discovered while on a different career path.

Michael Januska, founder of Old Brooklyn Cheese Company in Cleveland Ohio, made the jump to the cheese industry in the same way as many of his peers, in pursuit of a new passion discovered while on a different career path.

After graduating from the Southeastern Culinary Institute in Florida, Michael moved to London right at the beginning of a modern food explosion there. As an American chef overseas, he had a lot of diverse opportunities freelancing. “London has more Michelin Star restaurants than even NYC, it was the place to be for food and I soaked up as much as I could,” Michael recalls. During his 16 years there he met and learned from everyone he could – chefs, farmers, retailers – traveling all over Europe connecting with locals and eating in their homes. “People have different passions and it’s good to meet and learn what others are doing.”

While in London, Michael worked right around the corner from the original Neal’s Yard Dairy. He spent a lot of time there, speaking with them, buying their cheese and putting it on his menu more and more. “That’s where cheese started falling in place for me,” he says.

After moving back to his hometown of Cleveland, he decided rather than trying to restart as a chef in the U.S., he would embark on a new venture. He had already been making cheese at home as a hobby, teaching himself and absorbing as much content on the subject as possible. “Americans were making awesome cheese all over the country, but nobody was in Cleveland.” It was a gap he wanted to fill and in 2016, he opened Cleveland’s first brick and mortar cheese shop and production facility, Old Brooklyn Cheese Company.

After moving back to his hometown of Cleveland, he decided rather than trying to restart as a chef in the U.S., he would embark on a new venture. He had already been making cheese at home as a hobby, teaching himself and absorbing as much content on the subject as possible. “Americans were making awesome cheese all over the country, but nobody was in Cleveland.” It was a gap he wanted to fill and in 2016, he opened Cleveland’s first brick and mortar cheese shop and production facility, Old Brooklyn Cheese Company.

Over last few years, Old Brooklyn Cheese Company (OBCC) has grown and evolved, partnering with local retailers to get their seasonal raw cow milk cheese in consumers’ hands. In 2018, OBCC and their neighborhood of Old Brooklyn were selected by Cleveland Chain Reaction – an organization that puts money back into Cleveland neighborhoods through investors. With that investment they moved into a larger facility, upgraded their equipment, and increased cheese production.

In 2019, OBCC joined ACS as a member and exhibited at Meet the Cheesemaker in Richmond. “We joined to get to know more people in the industry. It’s small community and meeting all the cheesemongers, producers, distributors, and retailers at conference opened a lot of doors.” For him, it was an eye-opening experience, and getting the direct feedback on their cheeses was helpful.

But cheese isn’t the only thing made by Old Brooklyn Cheese Company, they also produce the award-winning Old Brooklyn Mustards. “We can only make cheese from March-October when the cows have grass to eat, and Cleveland is way into mustards, so it was a natural addition,” Michael explained. He partners with a local brewery, infusing mustard seeds with their IPAs to create a “time-release capsule that explodes with flavor” when crushed. They now sell two flavors, one of which, Pepped Up, won Best Pantry Item at the 2020 Good Food Awards.

“Being part of something that opens up access to the people that I need to know is very beneficial and ACS has been that for me.” Taking what he’s learned, Michael is now focusing on how to market his cheeses, take advantage of the expanded facility, and put Old Brooklyn Cheese Company products in more hands. “We now have room to perfect our cheese and process, it’s time to go, go, go!”

Learn more about Old Brooklyn Cheese Company at oldbrooklyncheesecompany.com , or follow them on Instagram, Facebook, and Twitter.

Couët Farm & Fromagerie

Marie-Laure Couët, founder of Couët Farm & Fromagerie in Dudley, Massachusetts, didn’t begin her career wanting to start a cheesemaking business. In fact, she graduated in 2009 from Brown University with a master’s in environmental studies hoping to go into environmental policy. During college, she spent a year in the Swiss and French Alps studying the environmental impact of local farmers and cheesemakers and learning about regional policies influencing the industry.

Marie-Laure Couët, founder of Couët Farm & Fromagerie in Dudley, Massachusetts, didn’t begin her career wanting to start a cheesemaking business. In fact, she graduated in 2009 from Brown University with a master’s in environmental studies hoping to go into environmental policy. During college, she spent a year in the Swiss and French Alps studying the environmental impact of local farmers and cheesemakers and learning about regional policies influencing the industry.

Graduating during an economic recession meant jobs were hard to find and Marie-Laure had to think outside the box for her future. During her time in Europe, she fell in love with the goats and farms she was researching, unearthing a new passion. “I tasted a chèvre for the first time in the Alps,” Marie-Laure recalls, “and it was unlike anything I’ve ever had.” This enthusiasm resulted in Couët starting the family operated Couët Farm & Fromagerie in 2015. She joined the American Cheese Society (ACS) as a member just one year later, in 2016.

Rather than splitting their time between cheesemaking and animal-care, Couët Farm & Fromagerie sources their milk from local cow and sheep farmers. This way, Marie-Laure and her team can focus on perfecting their award-winning, specialty cheeses. Couët cheeses have won awards 11 times since opening, four of which at the ACS Judging & Competition. “We originally joined ACS to take part in the competition; we wanted that feedback from experts in the industry,” she remarks, “the recognition and exposure has been crucial.” Since then, Couët has also experienced the value and community of her ACS membership outside of competition. “The network of support ACS provides, even from across the country, is wonderful.”

Rather than splitting their time between cheesemaking and animal-care, Couët Farm & Fromagerie sources their milk from local cow and sheep farmers. This way, Marie-Laure and her team can focus on perfecting their award-winning, specialty cheeses. Couët cheeses have won awards 11 times since opening, four of which at the ACS Judging & Competition. “We originally joined ACS to take part in the competition; we wanted that feedback from experts in the industry,” she remarks, “the recognition and exposure has been crucial.” Since then, Couët has also experienced the value and community of her ACS membership outside of competition. “The network of support ACS provides, even from across the country, is wonderful.”

Marie-Laure sees a bright future for Couët Farm & Fromagerie, carving out a niche through partnerships and experiences with other local businesses. They pride themselves in helping to strengthen their community through those partnerships, providing quality, fresh, locally sourced food. “There is a big opportunity here for Couët in agritourism and events and I’m excited for us to take that next step!”

Learn more about Couët Farm & Fromagerie at couetfarm.com, or follow them on <Instagram or Facebook.

Union Star Cheese Factory

Running and growing a small business can be challenging and requires owners to wear many hats, something Jon Metzig, co-owner of the family-run Union Star Cheese Factory in Fremont, WI, looks to American Cheese Society (ACS) to help support. A member since 2011, he sees ACS resources like the Best Practices Guide for Cheesemakers and Safe Cheesemaking Hub as crucial guides for cheesemakers. “ACS puts value in the education portion to help grow the industry and guide producers both small and large, something that I love and appreciate,” Metzig says.

Running and growing a small business can be challenging and requires owners to wear many hats, something Jon Metzig, co-owner of the family-run Union Star Cheese Factory in Fremont, WI, looks to American Cheese Society (ACS) to help support. A member since 2011, he sees ACS resources like the Best Practices Guide for Cheesemakers and Safe Cheesemaking Hub as crucial guides for cheesemakers. “ACS puts value in the education portion to help grow the industry and guide producers both small and large, something that I love and appreciate,” Metzig says.

The Metzig family purchased the factory from a dairy cooperative in 1911 and it has been family-owned and run ever since. Jon’s parents took over in 1980, surviving an agriculture crash and industry change because of the already successful retail shop they had previously opened. “One of my earliest memories was at 6-years-old, bagging cheese curds for a penny a bag,” Jon recalls, “I was always in the factory and around cheesemaking.” In high school he worked on local dairy farms and even got his cheesemaker license in Madison. After attending the University of Wisconsin for Agriculture Business and working two years for Crave Brothers Farmstead Cheese, Jon re-joined his family at Union Star. “When you grow up in an industry you can take it for granted, but after those experiences I realized there was so much more to food science and what it could do for our business.”

These days Union Star has increased its focus on specialty cheese, something they see a great future in for both cheese and their factory. In his experience consumers are becoming more accepting of, and willing to try specialty food as well as learn more about it. “Ten years ago, the average person wasn’t that interested in craft beer and now look at it,” he says, “It’s similar for cheese and that’s exciting!”

These days Union Star has increased its focus on specialty cheese, something they see a great future in for both cheese and their factory. In his experience consumers are becoming more accepting of, and willing to try specialty food as well as learn more about it. “Ten years ago, the average person wasn’t that interested in craft beer and now look at it,” he says, “It’s similar for cheese and that’s exciting!”

The industry shift towards specialty cheese often also come with new regulations. Metzig has found that it can be a challenge for producers to adjust and prepare, but reflected on how valuable their ACS membership has been during these times: “We love how ACS supports the smaller cheese organizations and the issues we face,” says Jon. “They are here for cheesemakers of all sizes.”

Learn more about Union Star Cheese Factory at unionstarcheese.com, or follow them on Facebook or YouTube.

River Whey Creamery

The American Cheese Society team works hard to provide resources to help our members’ businesses succeed. Members like River Whey Creamery in Schertz, Texas, have used those resources to help their creamery reach the next level.

“The amount of effort ACS puts into the education side is priceless for a smaller cheesemaker like me” says founder and owner of River Whey Creamery, Susan Rigg. Susan and River Whey Creamery have been members of ACS since 2015 and resources like the Best Practices Guide for Cheesemakers and the Safe Cheesemaking Hub have been crucial tools in nurturing the exponential growth they’ve seen since then.

“The amount of effort ACS puts into the education side is priceless for a smaller cheesemaker like me” says founder and owner of River Whey Creamery, Susan Rigg. Susan and River Whey Creamery have been members of ACS since 2015 and resources like the Best Practices Guide for Cheesemakers and the Safe Cheesemaking Hub have been crucial tools in nurturing the exponential growth they’ve seen since then.

After working in big box retail for so long, Susan wanted a new plan for the second half of her career and signed up for a cooking bootcamp program, then attended the Culinary Institute of America in Hyde Park, NY. “I was surprised to discover how much I loved cooking but knew I didn’t want to open a restaurant.” Cheese-based travel to the Cellars at Jasper Hill in Vermont, and Gorwydd Caerphilly and Quicke’s Cheddar in the UK was also paramount in her journey. Combining her newfound enthusiasm for cheese, her love for science-based projects, and the cheesemaking blood running through her veins (she is a first generation American with roots in Wales and England) she launched River Whey Creamery.

River Whey has come a long way since Susan gutted her own dining room to develop their first three cheeses. Now, leaning on ACS resources and the talented team she’s grown and developed professionally, River Whey is better able to innovate by bringing more testing in house and putting together taste and science to make the best cheese possible. “It’s an important part of my company culture to help people grow professionally, and ACS helps with that,” says Susan. While teaching new employees safe practices for cheesemaking, those ACS resources like the Lexicon & Glossary are crucial to River Whey Creamery.

Susan also credits River Whey’s growth to the connections she has made since joining ACS and attending conference year after year. “In Texas it’s scattered and vast and ACS helps connect me with other cheesemakers that I wouldn’t otherwise be able to.” It’s those connections Susan and River Whey have forged that helped pave the way to creating an innovative and original cheese – a goal achieved when their Indigo Ridge was accepted into the ACS Judging & Competition American Original category in 2019. “Community is so valuable and the one created by ACS is helpful, sincere, and without ego.”

Susan also credits River Whey’s growth to the connections she has made since joining ACS and attending conference year after year. “In Texas it’s scattered and vast and ACS helps connect me with other cheesemakers that I wouldn’t otherwise be able to.” It’s those connections Susan and River Whey have forged that helped pave the way to creating an innovative and original cheese – a goal achieved when their Indigo Ridge was accepted into the ACS Judging & Competition American Original category in 2019. “Community is so valuable and the one created by ACS is helpful, sincere, and without ego.”

“I am so proud of what ACS does and represents,” says Susan. “For me, ACS is the only organization for the cheese industry.”

Learn more about River Whey Creamery at riverwheycreamery.com, or follow them on Instagram, Facebook, and Twitter.